“Our engineers, without a medical or biomechanics background, easily used the Delsys EMG system to evaluate the effectiveness of exoskeletons in reducing work place injuries”

Are we approaching work correctly?

What do we mean when we say someone is a “hard worker”? The phrase summons the connotations of feeling exhausted after a long day, especially within more physically exerting professions. However, hard work should not necessitate the need for us to push our bodies to the limit of their capacity.

In 2019/2020, musculoskeletal disorders (MSDs) accounted for 30% of all work-related ill health cases, resulting in 8.9 million working days lost, in the UK. Workplace injuries not only cause harm to the physical well-being of employees, but the economic costs are a burden for companies. In the UK, last year it was estimated that ill health and work-related injuries resulted in a £16.2 billion cost to the economy. The prevalence of work-related MSDs across Europe is also well documented. In 2015, more than a third (37%) of EU workers stated that their work negatively impacted their health, with MSDs accounting for 70% of work-related health issues in countries such as the Czech Republic, Cyprus, Poland and Finland.

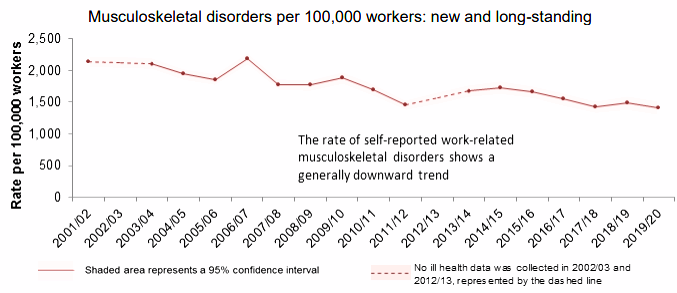

There has been a gradual downward trend in the number of work-related injuries over the last 20-years, as shown in Figure 1. This in part could be down to the increase in workplace ergonomics. However, a 2002 report from the Occupational Safety and Health Administration (OHSA) reported that only 26% of workplace injuries are eliminated by ergonomically engineering the work environment. Surely, is it not time to start questioning whether “hard work” should be adapted? We must start asking what more we can do to reduce the risk of injuries.

So, what is ergonomics?

Ergonomics, in essence, is an applied science concerned with how humans interact with their environment. By this definition, ergonomic decisions should be informed by physiological measurements of how our muscles, which govern movement, respond to occupational tasks.

MSDs are the major contributor to workplace injuries. Therefore, it is important that we understand the mechanics behind what causes the injury. The measurement of muscle activity can help to identify certain movements that elicit either high levels or repetitive activation of the involved musculature. Through investigating occupational tasks, we can start to identify “at-risk” activities and build interventions that look to reduce the overall muscle activity of the worker.

How can we adapt?

Electromyography (EMG) is the study of electrical activity produced by skeletal muscles. As De Luca (1997) stated, EMG:

“provides easy access to physiological processes that cause the muscle to generate force, produce movement and accomplish the countless functions which allow us to interact with the world around us”.

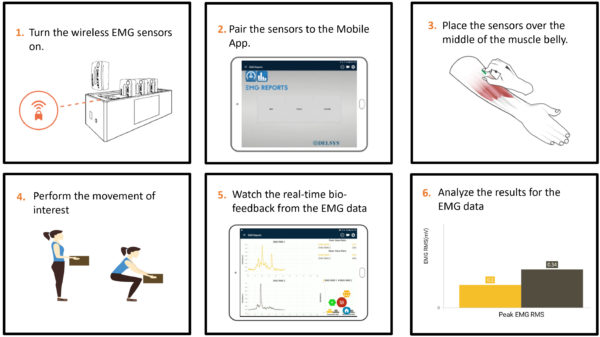

The marrying of EMG with ergonomics seems the natural way to offer a quantitative assessment of muscle activity during occupational tasks. Through constant innovation, EMG technologies are now fully wireless which allows users to acquire and analyse data easily through user-friendly mobile applications.

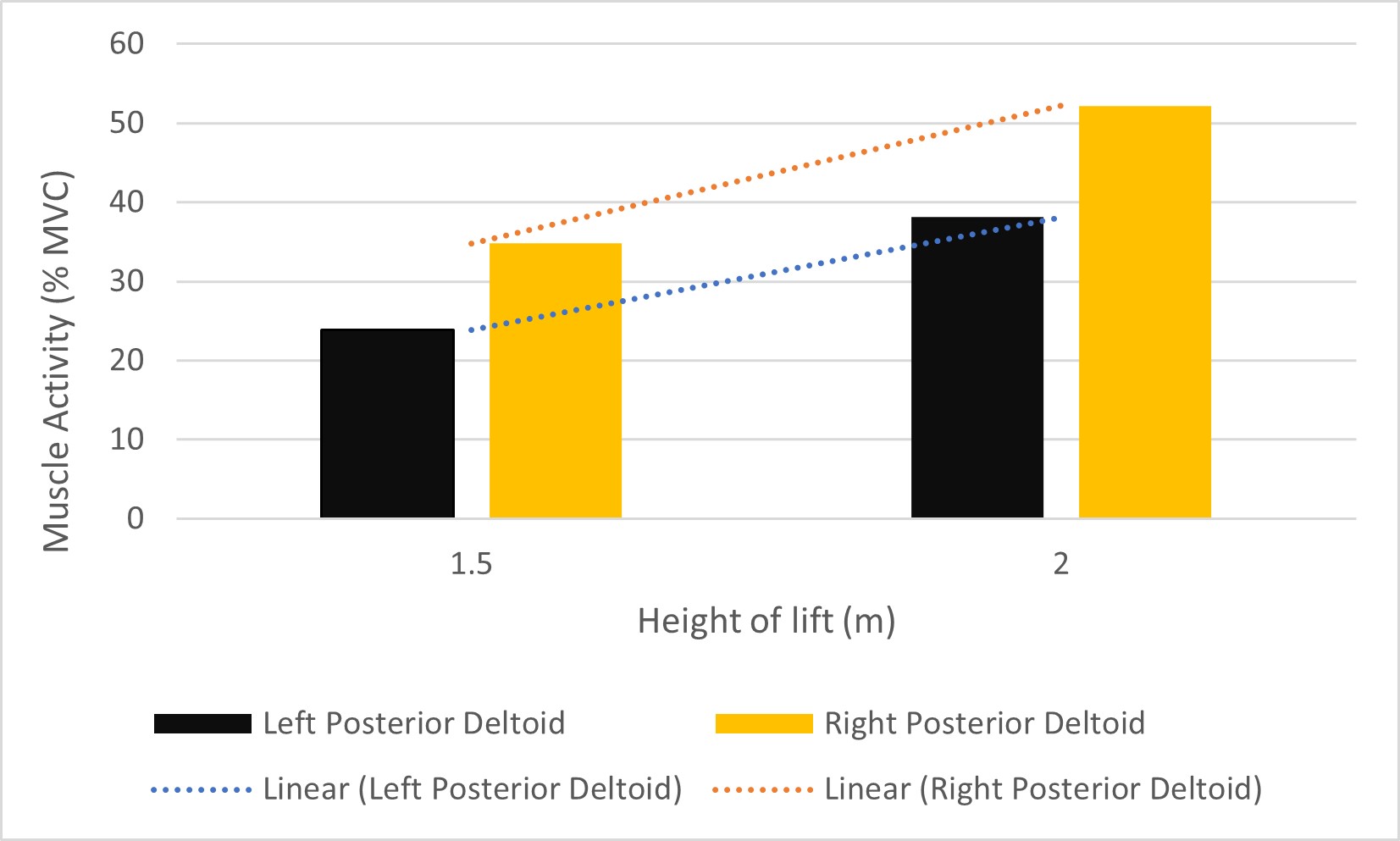

In the shown example (Figure 2), a Trigno Avanti Sensor was worn bilaterally on the posterior deltoid, a muscle that, as part of the upper limbs and neck category, accounts for 44% of all workplace injuries. Following the steps as shown in the attached diagram, two tasks were performed. In the first, the subject placed an object of mass 10kg on a shelf at a height of 1.5m. In the second, the subject placed the same object at a height of 2m. Figure 2 shows that, to place the object 50cm higher, the effort required increases by ~50%.

Sounds good, but does it work?

From recent surveys, construction has been shown to have some of the higher rates of MSDs. This is likely due to the heavy duty work that is done repeatedly during the day. Jaguar Land Rover realised the risk of injury to their employees and decided to act.

They stated…

“Jaguar Land Rover’s Manufacturing Research team have used the Delsys EMG system extensively to analyse the effects of exoskeleton devices on production line workers. By using the Trigno Mini Sensors, EMG data allows for objective, data driven measurements to assess the impact on the worker’s muscle activity. This provides a baseline to compare different devices to one another.”

So, the data can provide a key insight into evaluation of ergonomic interventions. But what good is the system if it takes an absolute expert to operate. Well, Jaguar Land Rover had their say on this as well…

“The ease of system setup and intuitive software combined with Delsys’ training courses has allowed JLR’s engineers to successfully use the system without a medical or biomechanics backgrounds. The wireless nature of the system has even allowed JLR to capture EMG data whilst workers operated the production line. The real-world application has proven extremely valuable in the evaluation of device effectiveness along with improving and developing future exoskeleton devices”.

Using EMG allows companies to assess the effectiveness of ergonomic interventions, such as the use of exoskeletons. Even more possibilities are within reach and exciting developments are still to come.

What may the Future Hold?

Technology, and the way in which we interact with it, is constantly evolving. With industry entering a new evolution, commonly defined as ‘Industry 4.0’, the concept of human-machine interaction (HMI) has been defined as a key pillar, in particular human-robot collaboration (HRC).

HRCs have been suggested as the next step forward in helping to reduce the biomechanical overload of workers performing heavy and repetitive tasks. The end goal would be to create a working environment that combines typical mechanical strength with human inimitable skills.

With the increased use of myoelectrical control within robotics, ergonomics may just well be one of the future applications. An EMG powered robot has the potential to recreate physical movement whilst minimizing the physical exertion of the operator. As is shown in the example below, EMG data can be used in a variety of ways to help lessen the load and mechanical work of the user.

The future holds many new possibilities, but one thing remains clear. We must adapt the way in which we approach “hard work”.

For further information about any of our EMG products and their application, please contact a member of the Delsys Europe team at contact@delsyseurope.com